304: Sunday 7th February 2021

303: Wednesday 3rd February 2021

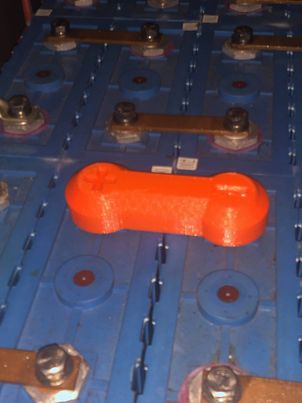

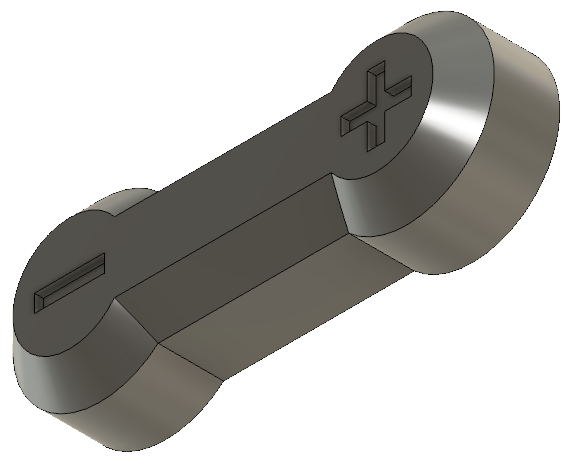

Finessed the design of the battery terminal cover. The photo below shows the larger v1 and the refined v5.

302: Tuesday 2nd February 2021

301: Monday 1st February 2021

In August 2017 I changed from DC drive to AC. Since then I have had no real issues to report. I have added Air Suspension, a new DC-DC converter and a GSM switch to remotely control the cabin heater by text messages. I haven't updated the blog since 2018. I have just been pretty much trouble free driving since then. It is coming up on the 12th anniversary of the conversion start and 11 years of being road legal. Now this year is "operation tidy up". Over the years I have tried many different systems and basically replaced everything at least twice. Apart from the Air Suspension I have been driving the same system of AC drive for the last 4 years.

300: Friday 28th December 2018

299: Thursday 23rd August 2018

298: Sunday 10th June 2018

297:Saturday 7th April 2018

296: Monday 2nd April 2018

295:Saturday 28th October 2017

I borrowed a 2 post lift from my friend and neighbour Luke for a weekend. On Saturday 14th October 2017 I had my friend Trevor Harding helping immensely.

----

Before we could get to the bolts we had to remove the trim panels in the back, but these were held down by the battery pack and it's racking. That was the first hour or so.

----

The struts went on fairly easily with a bit of release oil on the threads. Setting up the bottom height was a matter of trial and error to start with. Our friend Duncan Thomas turned up later to see how it was going and helped run the air lines from the rear struts to the valve block at the front.

----

On Sunday 14th October 2017, Duncan Thomas came along to help and we got the front struts fitted. After the experience of the rear struts, the front was easy, but ran out of time to do any setting for the bottom height.

----

While the drive battery was disconnected, the 12v system was getting no top up, and the battery wasn't great. When I cam to power up the compressor on Saturday it damaged the DC-DC converter so there was no recharging of the 12v system. I connected a mains charger to the 12v system on Sunday when we started and there was just enough juice to do the journey home. I had to order another DC-DC converter and I am still waiting for it to come from USA.

I saw an advert for some LED light strips for the rear lights and bought some from EBay. I fitted these and also installed a new electric aerial only to find I had 2 male connectors in the trunk. I have ordered an adapter with 2 female connector to join these together. That's something to watch out for when buying a universal fitting aerial.