When I win the lottery, I want to be able to get the Probatron a fresh coat of flashy paint and some scissor action door hinges. If I do win the lottery then I will make it into a convertible as well. An electric Ford Probe convertible with flippy up doors and a flashy paint, how cool is that? Until then, I can just try and scrape off some rust and make good everything underneath the bumpers. Starting with the front. I found a couple of bonuses in removing the front bumper, I could remove the redundant coolant filler tank and PAS cooler pipe that was all corroded. so that another approx 1kg off the weight. The picture below shows the front end stripped down and rusty. ----

Hopefully the next time I report on this it will be after I have dug all the rust off, brushed it all back and applied rust inhibitor, then I can start painting it and applying protection coats, then I can fit the bumper back on. I am contemplating changing the bumpers to some funky body kit as there are some rather smart ones out there for the Probe. I shall also have a go at updating the lights to include some LED strip instead of the normal side lights. The lights come apart fairly easily, so this should be fairly straight forward.

194: 28th May 2011

I have fitted the centre console back in the car, but I cannot remember if the PAS switch was "on" when I took it out of the old panel. It does not matter as there are no markings to say which is on and off. I know that I set it up so when it is off, the switch is illuminated. This is not a problem now as I don't have a gear lever in the way any more. It all went back together with no real problems. The only change I had to make was to the wiring between the FWD/REV switch and the stop button as they were no longer right next to each other, so I had to make a longer wire between them. Not really a problem. The photo below shows the view from the Drivers door.----

The next photo below shows the view from the passenger side.

The next photo below shows the view from the passenger side.

193: Friday 27th May 2011

I went and got some stock from the stationary section of my local supermarket to make up the centre console panel to mount the display and other controls. My local supermarket is huge and has everything, so I came back with a selection of coloured card, some spray glue, some glue sticks, and I had ordered some acetate sheets from eBay that came the other day. I took the panel that I had spent ages trying to paint and run a sander over it and took it all off. I didn't strip it right back, which worked to my advantage as it gave me a good keyed surface to stick to. I sprayed glue on the metal and let it go tacky for about 30 seconds, then applied a sheet of black card. I let it set for a few minutes, then trimmed it round with a craft knife. I modified the design I had before for the panel and made a reverse stripe that I printed using a laser printer onto red card. I cut out the stripe and sprayed the back of it with glue. After it had dried for about 30 seconds I carefully stuck it on top of the black card. I then got a sheet of white paper and marked the outline of the panel on it. I cut it out with scissors and then offered it up to the centre console with the metal panel behind it. Using a pencil I marked the edge of the hole in the centre console onto the white template. I took the template and cut just outside the line I had made, but I left it right up to the edges where the fixing points were so I could align it correctly on top of the plate again. I positioned the sheet and taped it through the holes to the back of the sheet to hold it in position and then sprayed glue over giving a layer of glue on the edge of the plate after I had peeled away the white template. I let this dry for 30 seconds and then applied a sheet of acetate and gripped it on all the way round where there was glue, being careful not to touch the centre as I had some of the glue on my hands by then. I then trimmed this up and cut out the holes for the controls, but I left the sheet over where the display will go as this offers protection from getting marked. Another advantage of this approach is that I can just "re-skin" it with another sheet of acetate if it gets damaged in future. The picture below shows the console with 2 of the controls loose fitted. I shall put this all back in the car tomorrow probably.

192: Sunday 22nd March

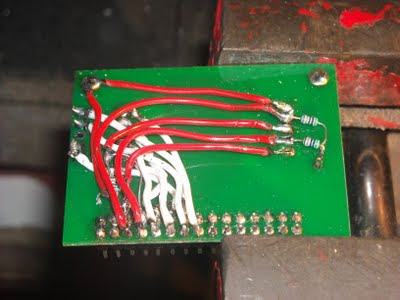

I have been trying to get the display working properly and decided to mount the capacitors on the display connector board using the solder pads provided. The picture below shows the back of the board with the connections made to the display connector from the solder pads. This is not my finest bit of soldering, but the connections are good.

----The next picture shows the top of the board with the capacitors mounted. I tried the display again, and it is still not working. I am not getting the LCD voltage to drive the display. Injecting the voltage shows the blue rectangle again, but when it was aligned to the correct voltage it was all black and you could see the dots being displayed, but that was all. I suspect the capacitors may be at fault as I ran all the codes suggested by the supplier and still the LCD voltage was not right, it was reading 0.16v and should have been -4v to ground. I have now ordered some surface mount capacitors and I shall mount them when I get them. I hope that works as I am not sure what else I can do now.

----

The picture below shows the plate for the controls and display to go into the centre console. I figured I would cut the rectangle for the display and then give a coat of gloss paint. I used the displayed rectangle to measure the actual display and then cut the rectangle with a hammer and chisel. The plate was so thin that any extensive filing or sawing would have distorted it dramatically. Chiselling was the best option and after I had made the first cut, I touched it up with a file to smooth the cuts out and get rid of burrs. I checked it with the display and made some minor adjustments with a file. I am not exactly sure how I am going to secure the display. I shall probably glue some spring clips to the back that the display can slide into.

----

I applied gloss black paint and allowed it to dry for a while. When the paint was still tacky I applied the graphics that I had printed off. The Forward, Reverse and PAS were made with a tape printer. I made these some time ago when I made the original panel. A quick coat of clear over the top of it all then it is ready to mount the switches etc. and fix it all back in the car. I shall come back to the display when I have it working as there is a lot to do even once I have some basic information showing on the display. The batteries will be monitored by two eight channel A to D converters through linear opto-couplers. The A to D converters shall be linked to a PIC chip through a serial port and the PIC chip will also handle the display of the levels on the screen.

191: Thursday 19th May 2011

I keep forgetting to mention that I got a write up in the Revenge of the Electric Car, click to go there. That was a bit random, but it came about because of a comment that I left there and I was contacted by email. I had a conversation on the phone with the graphic display supplier Technical Director who turns out to be a real keen electronics person and knows all about the display. He had emailed me to show that my display was working after I sent it back for testing. I need to pick it up from the post office now as he has sent it back. I am pleased to know it is working and I also noticed in the photo that I had bought the wrong display type and that the circuit that he had the display connected to had the DC-DC converter LCD voltage capacitors mounted. We discussed this and the board that I got from Newhaven displays has some solder pads that happen to be just right for mounting the capacitors, so I did this last night and this then gets them off the prototype board and closer to the display itself. Hopefully I can get this working now. I shall post some photos of the capacitors mounted on the board soon. This display is a reflective type and I was expecting an illuminated type, white on a blue background. I can use this for testing and then just swap it out for the white on blue display when I get one. They do have the same connections, but they also have an LED back light that just needs some power. This photo shows my actual display, so I know it works now and I can set about improving my test set up.

190: Sunday 15th May 2011

Yesterday I spent the day with my friend working on his car, but I took the opportunity while I was there to grab a piece of aluminium sheet and knock up the panel for the centre console. I then went on to fix an MiG welder he had that was not working how he wanted. The MiG wire would stay live when you were not feeding, and he wanted it to switch off the welding current when the feed trigger is released. So I obliged, but it did take a lot longer than I expected. So onto Sunday and the upgrades begin. First I removed the gear lever. For this I had to jack up the car and put stands under it, then remove the bolts from the gear selector rod and the support rod at the gearbox end, then back inside the car to undo the four bolts holding the gear lever. This then dropped down onto an old heat shield (another old surplus part that I need to remove at some point) and with a bit of jiggling I pushed it forward and then it dropped down. The photo below shows the complete gear lever removed. While I was underneath I went searching for a rattle that I was getting for the back end of the gear box. This normally occurred when releasing the throttle pedal and the Regen braking drag slows the car. I found that the rear gear box mount had all three bolts loose. This was not coincidence, I must have done them up hand tight and forgot to finish them off when I mounted the gearbox. Otherwise they have worked loose. Either way, they are tight now and I should not hear that rattle again.

----I took the panel that I had made on Saturday and applied it to the console. There were 2 main problems to start with. Firstly the cut-outs for the screws needed some filing as the panel would not go on and secondly I had put the curve in the plate the wrong way, so I needed to un-curve it and curve it the other way. I then went about removing the old panel from the upright part of the centre console. While I was doing this I realised I had the Zapi motor controller programmer unit hanging on to Tom Tom bracket on the vent flaps with cable ties for some time now. The unit had warranty void if removed stickers on the side, but I figured it must be beyond warranty now anyway, so I broke the seal and found that the circuit inside sits on spacers. This meant that there was a void underneath the circuit board, so running a couple of screws through the case to fix a mounting bracket to the back of the case was not going to be a problem. I took a strip of 3mm aluminium bar and fashioned a bracket that slipped under the edge of the centre console face plate with no screws showing. After many adjustments I fixed the bracket to the back panel of the unit and gave it a quick spray of Matt black paint so the bracket would be hidden. While the paint was drying I made some elbow clip to clamp the plate from the screw fixing holes to the new plate for the lower centre console. They did clash with the fixing points for the console itself so I had to rework them a few times. When I fitted all together I found the new plate was clashing with the upright centre console, so I needed to trim it to prevent this. I had a pair of aviation shears for trimming sheet metal, so I dug them out, tightened up all the joints and give them a go. To my dismay they just came apart and bent the metal rather than shearing it. They are now consigned to the scrap bin and I took out my hack saw and started hacking. After much tapping and banging I eventually got the sheet back to the same shape as before and offered up the controls to check the layout I had drawn. I preferred to have the PAS and emergency stop button swapped giving more separation between the forward reverse switch and the emergency stop button.. I used the old plate as a template and marked the new plate with a pencil. I used a spade drill to make the holes as I did not have any 22mm twist drills. I know this was meant for wood, but the aluminium was so soft and thin that the spade drill had no trouble cutting it. The PAS switch needed a 12mm hole and I had a drill for that. A quick touch-up with a file and the holes were done and the plate was read for painting. I keyed the surface with some sandpaper, but the first rub over was a little bit too course, so the first coat of paint had lines in it. I gave it a light rub over with some fine paper and another coat of paint and hopefully it will dry a lot better. I then went back to the Zapi programmer and mounted this in the car. It looks so much better now and I can get to my radio and mount my Tom Tom again. The photo below shows after the first coat with 2 of the controls loose fitted. I have since repainted it and hopefully I can start on the graphics to stick on before the clear coat goes on. I might need to use a gloss paint instead if the coverage does not improve as this tends to be slightly thicker and cover marks better.

189: Friday 13th May 2011

Today my batteries went back to the supplier for a part refund, so now the Probatron is off the road until I get some more batteries. Now I can work on upgrades to the car and fixing some of those niggling problems that I keep putting off. If I have time I may even take off the bumpers and clean up the rusty bits underneath. I have had the Probatron in 3rd gear now for about 4 months and never had the need to change gear at all. For my motor and controller and gearbox, third gear is fine. So I have decided to remove the gear lever, make up a panel for where the gear lever was and mount some of the controls in this new panel. It will make for easier access to the forward / reverse switch and also it gives me somewhere to mount the new display that I am still working on. The picture below shows a mock up of the graphics that I will have on the panel. This also shows roughly where the forward / reverse switch, emergency stop button and PAS switch would be mounted and also the display.

----

The next picture shows the back of the centre console with the gear lever gaiter still in place. This has a plastic flange that screws on in four places, so this means there are four fixings ready to go. I took this off and removed the gaiter from the flange. I could cut the flange, but it will be just as easy to make some bent aluminium strip to fix the new panel on the back of the console.

----

The next picture shows the centre console removed with the gear lever gaiter still in place. This is where the new panel will go.

----

The next picture shows the centre console with the mock up mounted behind. I used some cardboard to support this and just taped it on the back side. This was just to check the positions of everything, check the angles and just get a feel for how it will ultimately look. The graphics will be white on a black background.

----

The next picture shows the back of the centre console with the gear lever gaiter still in place. This has a plastic flange that screws on in four places, so this means there are four fixings ready to go. I took this off and removed the gaiter from the flange. I could cut the flange, but it will be just as easy to make some bent aluminium strip to fix the new panel on the back of the console.

----

The next picture shows the centre console removed with the gear lever gaiter still in place. This is where the new panel will go.

----

The next picture shows the centre console with the mock up mounted behind. I used some cardboard to support this and just taped it on the back side. This was just to check the positions of everything, check the angles and just get a feel for how it will ultimately look. The graphics will be white on a black background.

188: Wednesday 4th May 2011

I haven't mentioned much about batteries recently as I have been discussing this with my supplier. They had them for testing for 3 weeks and confirmed they were just about cycled out. I had them back and I have been getting about 7 miles before slowing down where I was getting around 40 miles when they were new. They have offered to buy them back for half the money I paid. Since the warranty was for 1 year and I have had over 8 months use, I have accepted this, so next week they will go back and I will get the cheque. I am not going back to Lead Acid batteries unless some recycled ones come along real cheap like the first set I had. I have some money coming in soon and hopefully I can drum up enough to get lithium batteries. I have decided to buy the batteries in stages and I shall start with 60Ah and 128v. This is 40 batteries in a string. I shall add another string of the same batteries at a later date when I have saved some more money. I realize this is not ideal, but it is what my budget allows for.

----

On the display subject, I have tried the test process recommended by the display supplier and it is just the same. I believe the display is damaged and I need another to verify this. Hopefully I can send this one back and the supplier can test it.

----

On the display subject, I have tried the test process recommended by the display supplier and it is just the same. I believe the display is damaged and I need another to verify this. Hopefully I can send this one back and the supplier can test it.

Subscribe to:

Posts (Atom)